मोटर इन्जिन स्पेयर पार्ट्स

मशीनिंग एल्युमिनियम भागहरू

हामी यसमा विशेषज्ञ छौं:

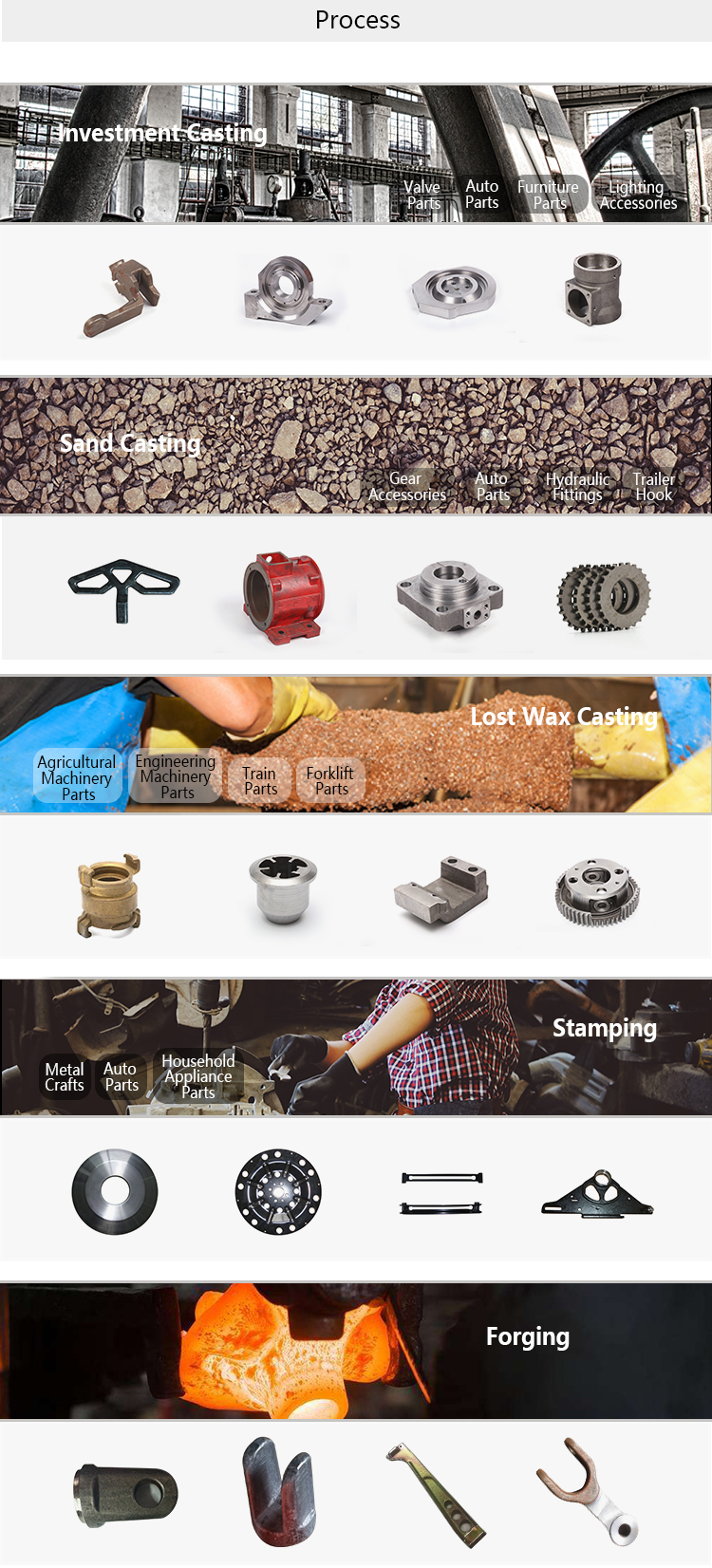

1 बालुवा कास्टिंग (खैरो फलाम, डुफलिटल ईन्टिमिल, एल्युमिनियम आदि)

2 लगानी कास्टिंग (कार्बन स्टील, स्टेनलेस स्टील, बिल्कुल स्टील, आदि)

3 मर्न कास्टिंग (एल्युमिनियम, जिंक, आदि)

4 मशीनिंग (CNC केन्द्र, सीएनसी लेभ, लात, ड्रिलिंग मेशिन, मिलिंग मेशिन, मेशिन, प्रेसिंग मेसिन, प्रेसिंग मेशिन, आदि)

प्रमाणपत्र: ISO9001: 201 2015, TS1694949

हामी कस्तो प्रकारको उत्पादनहरू प्रस्ताव गर्न सक्छौं?

|

Products

|

According to the customers' technical drawings or samples

|

|

Casting Material

|

Cast Iron, ductile iron, Grey iron, GG25, GG20, GGG40, GGG50, GGG60 GGG70:

|

|

QT400-18,QT450-10,0T600-3QT700-2,FCD400,FCD450,60-40-18,65-45-12,ect.

|

|

Casting Product Weight

|

available from 0.02kg to 3000kg

|

|

Surface Treatment

|

Oxidation

|

|

Plating zinc

|

|

Painting

|

|

Hot galvanized

|

|

Powder coating

|

|

Electroplating

|

|

Sand blasting

|

|

Electrophoresis

|

|

Vbration Grinding

|

|

Inspection

|

*100% ins pection before shipping, offer the material reports and mechanical property reports

|

|

*Control Plan and PPAP documents according to the clients'requirements

|

|

*ISO9001: 2015 quality control system

|

|

Extra Service

|

CNC machining servce in our machining workshop

|

|

Advantages

|

* The dimensions and outs ide shape are similar with investment casting

|

|

*The surface roughness is good from 2.5 to 25um(100 to 1000um

|

|

*The min thickness can meet 3 mm(0. 120inch)

|

|

*decrease the internal crack and keep close structure

|

|

*As no joint and defect the cleaning and machining work can be less

|

|

*it's cheaper because its a simpler process and the foam is cheaper than the wax

|